Editor | Green Luo

Synthesis of higher alcohols (HAS) through thermal catalytic hydrogenation of syngas remains a promising technology. Chain growth and CO insertion requirements require multicomponent materials whose complex reaction kinetics and broad chemical space do not meet catalyst design specifications.

Here, researchers from ETH Zurich propose an alternative strategy to integrate active learning into experimental workflows, using the FeCoCuZr catalyst series as an example.

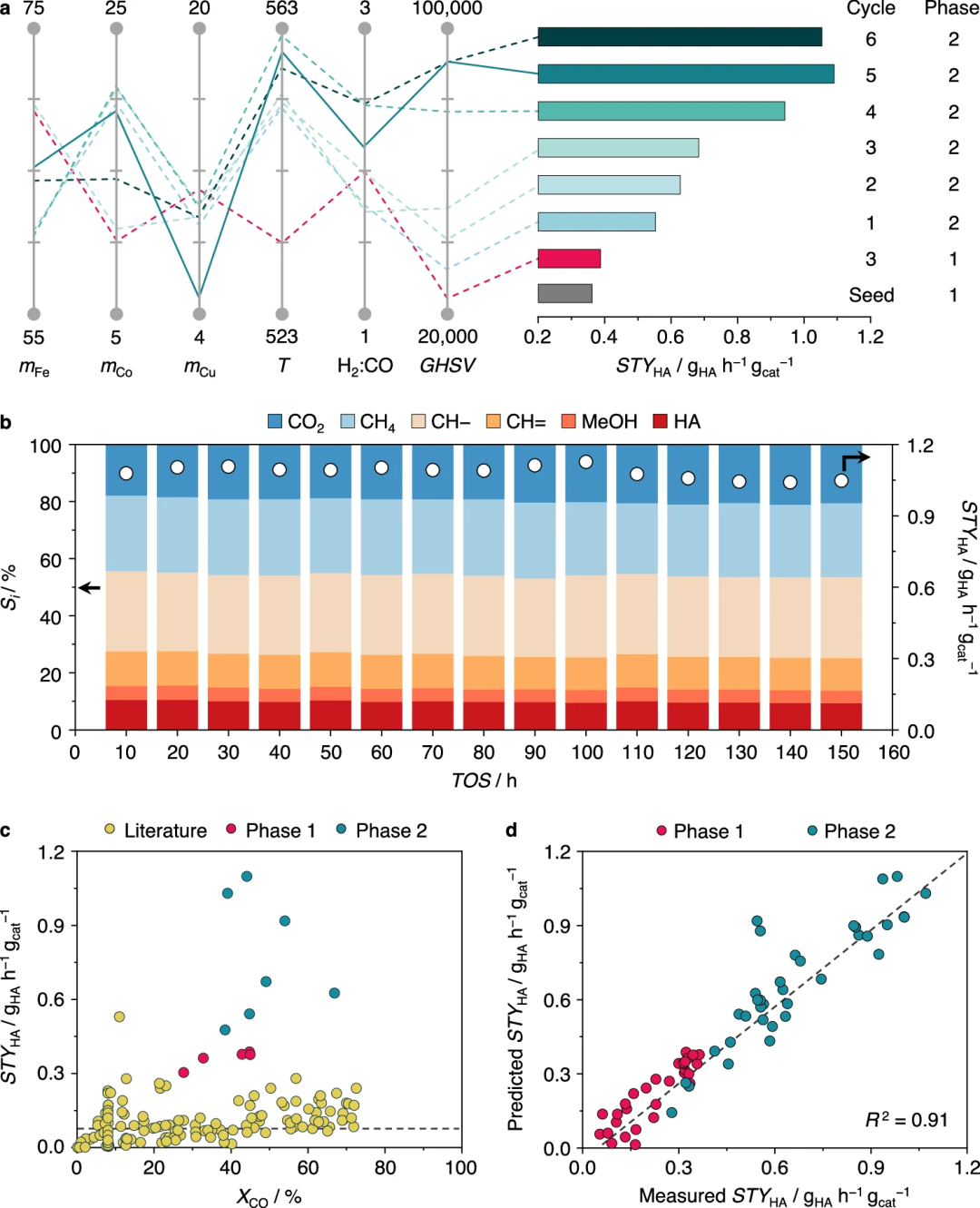

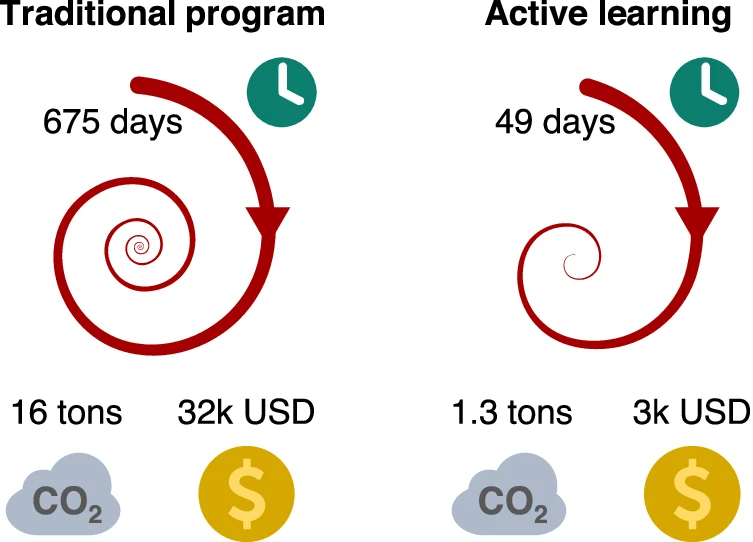

The proposed data-assisted framework simplifies navigation of a wide space of compositions and reaction conditions across 86 experiments, reducing environmental footprint and cost by more than 90% compared to traditional procedures. It was determined that the Fe65Co19Cu5Zr11 catalyst with optimized reaction conditions achieved a higher alcohol productivity of 1.1 at stable operation for 150 hours, a 5-fold improvement over commonly reported yields.

at stable operation for 150 hours, a 5-fold improvement over commonly reported yields.

This approach goes beyond existing HAS catalyst design strategies, is applicable to a wider range of catalytic transformations, and promotes laboratory sustainability.

Related research titled "Active learning streamlines development of high performance catalysts for higher alcohol synthesis" was published on "Nature Communications" on July 11.

Developing efficient catalysts for syngas-based higher alcohol synthesis (HAS) remains a challenge A daunting research challenge that could reduce fossil fuel production of valuable chemicals and fuel additives while promoting a circular economy and mitigating climate change issues. Providing fossil fuels for the production of valuable chemicals and fuel additives.

The intersection of machine learning (ML) and parallel experimentation is active learning, which is suitable for accelerating materials design and process optimization through a small data-machine intelligence-human decision-making closed-loop framework.

Although this approach is increasingly popular in materials science, drug discovery, and biosystems engineering, it remains underexplored in the field of catalysis. Whether active learning-assisted methods are suitable for highly complex HAS catalyst systems is unknown.

In this study, researchers pioneered an active learning strategy to accelerate the development of highly active FeCoCuZr catalysts. The main features include:

(i) Fe65Co19Cu5Zr11 catalyst has high predictive ability, and its optimal reaction conditions are stable higher alcohols with a space-time yield (STYHA) of 1.1  and a duration of at least 150 h, which is Highest value reported so far for syngas direct HAS;

and a duration of at least 150 h, which is Highest value reported so far for syngas direct HAS;

(ii) Significant reduction in time and resources by identifying optimal systems for 86 experiments from a huge space of approximately 5 billion potential combinations;

(iii) More Targeted optimization reveals inherent performance trade-offs and recommends Pareto-optimal catalysts to minimize selectivity to CO2 and CH4 while still maintaining high STYHA.

These results highlight the potential of data-driven approaches to continue to accelerate the development of efficient multicomponent catalysts and promote innovation in catalysis research.

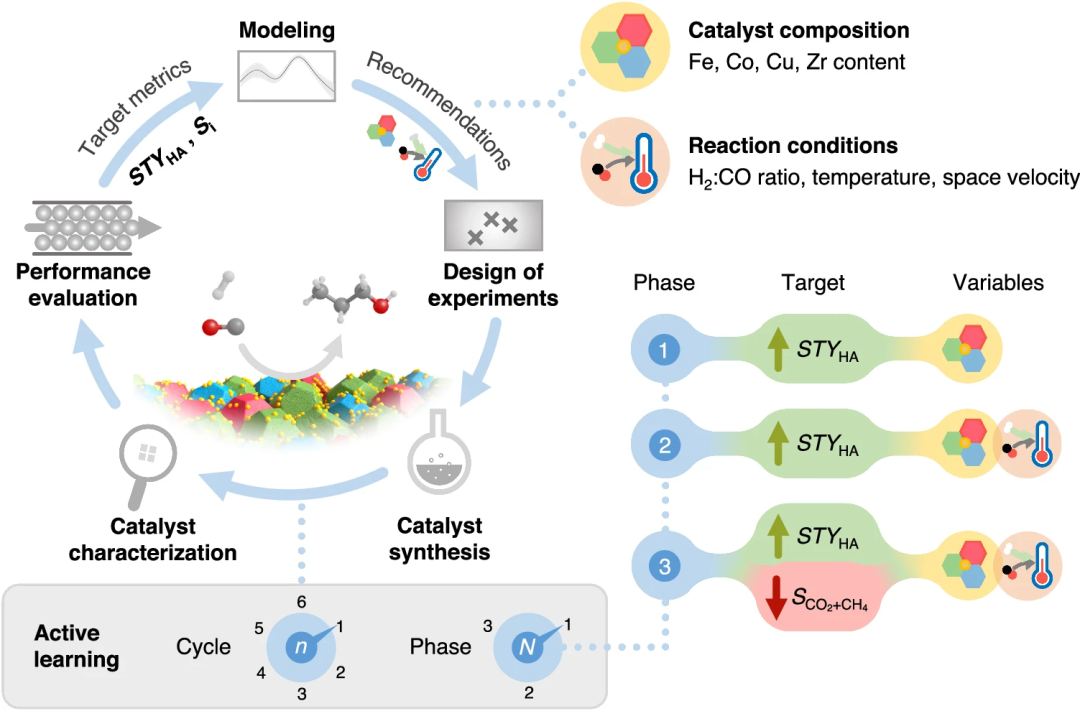

Active learning approach that combines data-driven algorithms with experimental workflows that continuously learn from existing and newly generated data in iterative experimental cycles to explore and identify FeCoCuZr composition and reaction conditions to optimize the catalyst performance indicators of interest. The core of the data-driven model combines Gaussian Process (GP) and Bayesian Optimization (BO) algorithms with human decision-making to complete single or multi-objective tasks.

Illustration: Active learning workflow scheme for the development of FeCoCuZr catalyst. (Source: paper)

To demonstrate the feasibility of this approach for HAS, the study was conducted systematically in three different phases, gradually increasing the complexity of the model.

In stage 1, the catalyst composition is varied with the goal of maximizing STYHA under fixed reaction conditions.

In stage 2, the dimensionality of the problem is increased by simultaneously exploring catalyst composition and reaction conditions to maximize STYHA.

Then, in stage 3, the method is extended to multi-objective capabilities by simultaneously maximizing STYHA and minimizing the combined selectivity of CO2 and methane. Each stage performs an iterative cycle consisting of six experiments until the target performance index is reached or saturation is reached.

While there are a billion combinations of possible chemistry and parameter space for FeCoCuZr systems, practical studies of multicomponent catalysts range from hundreds to thousands of screening experiments.

By employing active learning, the researchers mapped the vast space of FeCoCuZr catalysts into a cumulative 104 experiments in stages 1-3 to meet the required performance targets, confirming the growing literature claiming that active learning can speed up experiments Work. This has profound implications for the environmental and economic sustainability of catalyst development programs that have yet to be explored.

In this context, assuming that this study represents a catalyst development effort, the study evaluates the extent to which active learning affects two sustainability pillars of the laboratory.

Analysis shows that carbon footprint and costs are reduced by over 90% on average compared to traditional events. It was also observed that this result has very little dependence on global regional differences, affecting, for example, the energy mix or the composition of laboratory operating expenditures.

Thus, active learning significantly contributes to the development of sustainable catalysis laboratories by reducing the consumption of chemicals and energy, and optimizing resource utilization.

Note: The cover comes from the Internet

The above is the detailed content of Cost reduction by more than 90%, 'active learning + experimental workflow' accelerates catalyst development. For more information, please follow other related articles on the PHP Chinese website!