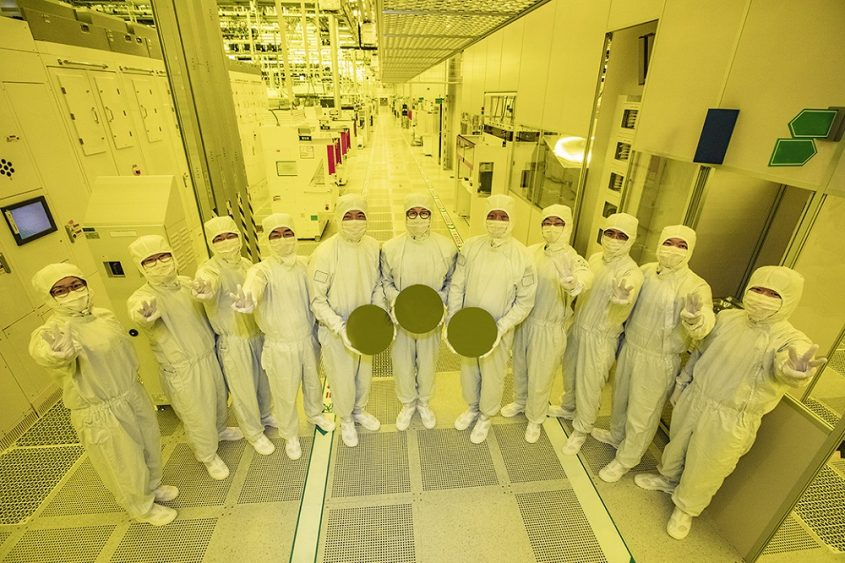

According to news from this site on March 7, Korean media DealSite recently reported that Samsung Electronics’ 3nm process yield is still worrying.

This site noticed that DealSite’s report only generally mentioned 3nm, without specifically mentioning which process it was.

Sources said that Samsung’s 3nm yield rate is still hovering at the 50% level and has not reached 60%. Although some analysts believe that it has reached more than 70%, the current GAA process is still not stable enough to ensure the yield.

There are different opinions about the yield rate of Samsung’s 3nm process. Some of the news after Samsung announced mass production are summarized as follows:

In May 2023, Samsung announced that its 3nm process The yield rate can reach 60~70%;

In July 2023, the institution Hi Investment & Securities claimed that Samsung’s 3nm yield rate reached 60%;

In October 2023, Korean media Chosunbiz said that Samsung’s 3nm yield rate was about 50%; The yield rate of the manufacturing process has been increased to more than 60%.

Regarding Samsung’s 2nm process, DealSite still regards it as the SF2 process that will start mass production in 2025.

It has not adopted what ZDNet Korea recently called “the second-generation 3nm process name change” 2nm” statementIndustry insiders believe that although Samsung Electronics lags behind in the 3nm process, if Samsung Electronics can gain a firm foothold in GAA technology, it can ensure competitiveness in 2nm and regain its title of "number one in foundry share." The client’s expectation to disperse its reliance on TSMC will also be a boost for Samsung.

The above is the detailed content of Sources say Samsung's 3nm process yield is still poor, less than 60%. For more information, please follow other related articles on the PHP Chinese website!

chip

chip

Does inflation rate have an impact on digital currencies?

Does inflation rate have an impact on digital currencies?

Unable to connect to the internet

Unable to connect to the internet

What does it mean to connect to windows?

What does it mean to connect to windows?

What is the use of docker image?

What is the use of docker image?

How to check if mysql password is forgotten

How to check if mysql password is forgotten

The difference between heap and stack

The difference between heap and stack

How to switch between full-width and half-width

How to switch between full-width and half-width