·"Competition is always cruel, and there is never mercy or opportunity for the weak. This is especially true in the competition of industrial products. A large industry can only tolerate 3 companies. The third company is struggling, and the fourth company will be early." You should be out."

"Competition is always cruel, and there is never mercy or opportunity for the weak. This is especially true in the competition of industrial products. A large industry can only tolerate three companies. The third company is struggling, and the fourth company has long been It should be out." On September 19, during the 23rd China International Industrial Expo, Shanghai Jibot Robot Co., Ltd., an industrial robot R&D and manufacturer, launched its first industrial collaborative robot. Jiang, Chairman and President of Jibot Robot Yao said that the development path of domestic industrial robots is high configuration, high performance, and high cost performance, that is, defining and designing products according to the same standards as leading companies in the industry, and ultimately achieving "world-class cabbage prices."

Collaborative robots can be used in human-machine collaboration environments, with a wider working range, drag-and-drop teaching, simpler user interface and programming, and low deployment costs. Jiang Yao said that collaborative robots have been around for more than 10 years. The current market structure of collaborative robots is "one super, many strong". "One super" refers to Universal Robots, the Danish robot company that invented the concept of collaborative robots. "Basically all industrial collaborations "Arm developers design collaborative robots based on its basic configuration and principles." "Duoqiang" refers to a group of local collaborative robot companies that have emerged in China since 2014.

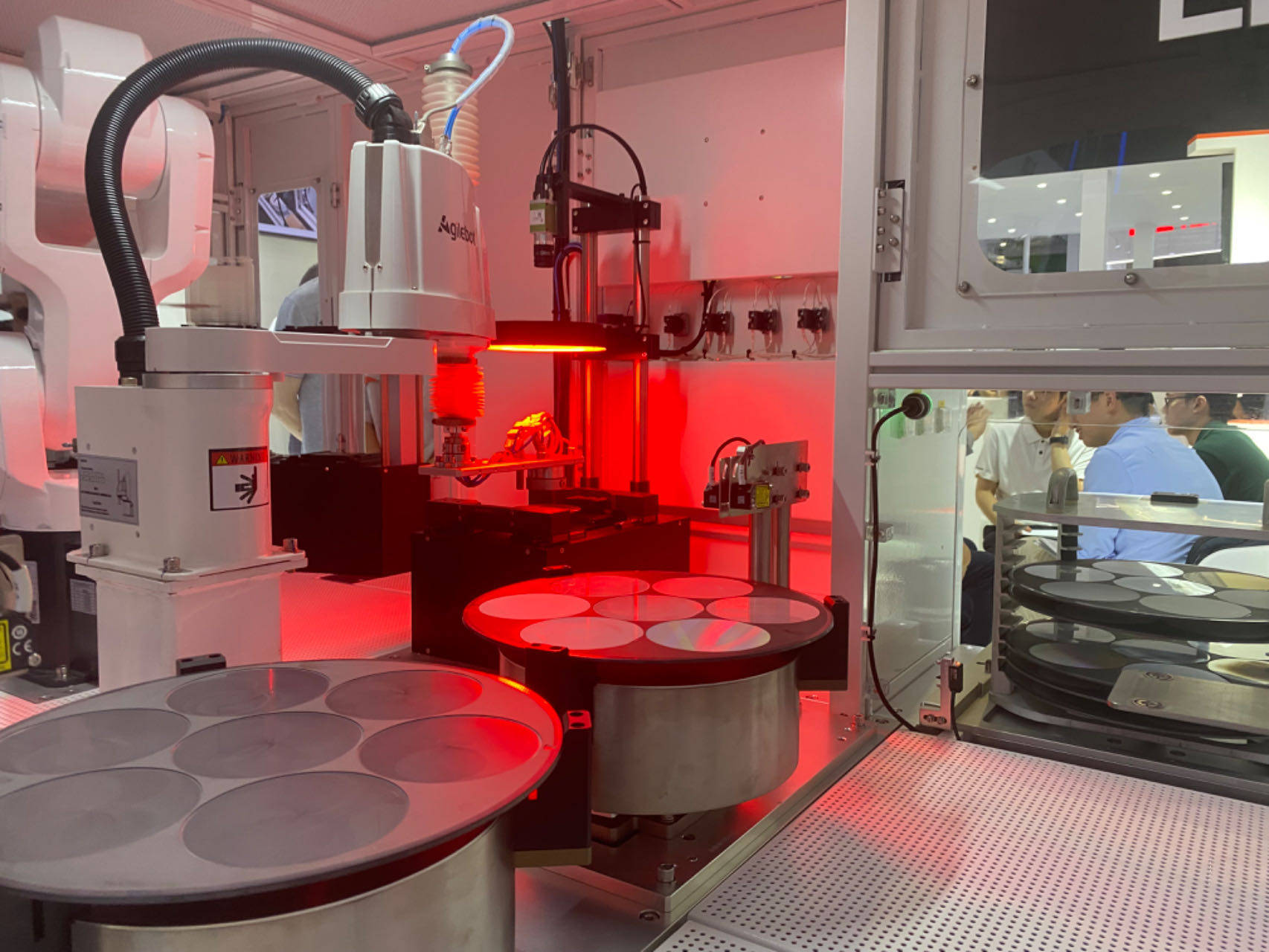

Jebot PVD (Physical Vapor Deposition) automatic wafer rewinding machine is a piece of equipment that needs to be rewritten

Robots are hailed as the crown jewel of the manufacturing industry, but the reality is that the robot industry is seriously involved. Jiang Yao said bluntly that “it doesn’t have the taste of a pearl”, “Many teams that have joined involution have problems with their methods, which include assembly-based and brick-and-mortar development, lowering standards, lowering performance, lowering costs, and lowering sales prices, which ultimately leads to a negative cycle. The vicious circle is getting more and more complicated, disrupting the market. Positive competition is to achieve world-class performance."

He believes that foreign robots have high configuration, high performance, and high price. Therefore, domestic industrial robots must follow the development path of high configuration, high performance, and high cost performance, that is, defining and designing products according to the same standards as the leading companies in the industry. , and finally achieve “world-class cabbage price”. "Now we are engaged in 'outsourcing', relying on high configuration, high performance, and high cost performance, so that domestic robots will one day stand at the C position of the exhibition. Without these 'three highs', domestic robots will always be second-rate or third-rate."

Jebot GBT-C5A-850 is an industrial collaborative robot

Jebot Robot has launched the GBT-C5A-850 industrial collaborative robot, which is the first product after the industrial 6-axis robot series and the SCARA robot series. The robot has a payload capacity of 5kg and a working radius of 850mm. It can be taught through Android APP and Windows software, and can be taught wirelessly through mobile phones, tablets and other terminals. Jebot Robot adopts the reducer products of Suzhou Green Harmonic Transmission Technology Co., Ltd., and also independently develops systems, algorithms and electronic hardware, and adopts single-chip multi-axis drive and control integrated technology. Compared with foreign collaborative robots, Gebot Robot's GBT-C5A-850 collaborative robot product provides the first batch of trial users with a price of less than 40,000 yuan, redefining the price system of industrial collaborative robots. Jiang Yao said that just like the development of my country's photovoltaic, panel and other industries, as long as local companies master core technologies and build their own supply chains, they will be able to provide local users with products with unexpected cost performance

The above is the detailed content of President of Shanghai Jibot Robot: Collaborative robots are extremely competitive and should actively promote positive competition. For more information, please follow other related articles on the PHP Chinese website!