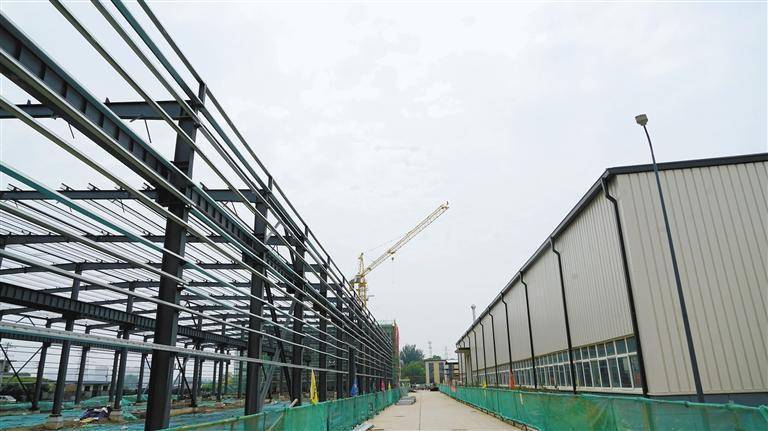

The second phase of the Jiahan Global New Power Transmission Manufacturing R&D Center project is under construction. Photo by Shaanxi Daily Correspondent Xie Tao

Right now, it is the golden period of production and construction. In Jingyang County, one after another major projects are anchoring the node and "hurrying up", and the enthusiasm for hard work and quick work is surging everywhere.

On June 2, the reporter walked into the Jiahan Global New Power Transmission Manufacturing R&D Center located in Linkong Intelligent Manufacturing Park, Jingyang County. In the production workshop, several workers cooperated tacitly and were debugging precision parts. The intelligent production line nearby was operating at full capacity. I saw industrial robots waving their arms up and down regularly under program control, carrying, spraying, packaging...

Every component produced here has a chip or QR code as an "ID card", which can realize one-second identification and full traceability.

"The project started construction in April 2020. The first phase includes 4 factories, 6 finishing production lines, office buildings and other supporting facilities. It is currently put into use. The second phase of the project is under construction and will be completed this month Completed." Project leader Chen Shan said.

It is understood that the Jiahan Global New Power Transmission Manufacturing R&D Center project covers an area of 118 acres and was constructed by Shaanxi Hanyue Equipment Manufacturing Co., Ltd. with an investment of 500 million yuan. It is mainly engaged in core components such as wind power generation, rail transit, and high-end precision machine tools. R&D, manufacturing, assembly, and production of involute technology robot reducers.

With the accelerated pace of transformation and upgrading of my country's manufacturing industry, industrial robots are widely used in high-end equipment manufacturing fields such as rail transportation, wind power generation, heavy-duty trucks, and high-power engineering machinery. As one of the core components of industrial robots, reducers have long relied on imports.

Chen Shan told reporters that after years of independent development of core technologies, the company has mastered the world-leading involute robot reducer technology with independent intellectual property rights. "This technology is superior to traditional cycloidal technology reducers in six aspects including accuracy, stiffness, life, efficiency, transmission power density, and cost, and has 21 patents. We have also participated in the formulation of 4 industry standards, and our products have been exported to Germany. , France, the United States and other countries." Chen Shan said.

From a traditional manufacturing enterprise to a high-end equipment manufacturing enterprise with strong technological innovation competitiveness, technological innovation has enabled the enterprise to achieve leapfrog development. Today, the company has become a "super smart manufacturing factory" with an annual production capacity of 2 million pieces of various parts.

Yang Sheng, the project production line leader, was deeply touched by this: "It used to take half an hour to an hour to manually check the parameters of each production line every day. Now, all parameters are set by designers in the background and the control range is locked. The production line can produce thousands of small precision mechanical parts per day.”

The introduction of this project is of great significance to Jingyang County in accelerating the development of high-end equipment manufacturing industries represented by power transmission and distribution equipment and power transmission systems.

Behind the establishment of technology-based enterprises, it is inseparable from the "technological innovation soil" carefully cultivated by the local government. In recent years, in order to speed up its integration into the Qinchuangyuan Science and Technology Achievements Transformation Pilot Area, Jingyang County has accelerated the creation of a “one district, two parks” industrial platform (Jingyang Linkong Urban Area, Linkong Intelligent Manufacturing Park, Linkong Science and Technology Innovation Park), and increased investment promotion. Strengthen efforts, concentrate resource elements, and refine implementation policies. By establishing a green channel for the implementation of Qin Chuangyuan projects, priority will be given to ensuring the implementation of flagship and chain-main high-end equipment enterprises.

"So far, Jingyang County Linkong Intelligent Manufacturing Park has introduced 16 industrial projects such as Shendian Electrical Appliances, Jiahan Mechanical and Electrical, Six-ring Transmission, and Aobang Heavy Industry, with a contract value of nearly 10 billion yuan." Jingyang County Industry said Zhang Bin, deputy director of Xincheng. The high-end equipment manufacturing industry has become a powerful engine for the economic development of Jingyang County.

In addition, the Jiahan Global New Power Transmission Manufacturing R&D Center project can provide 500 jobs and become an important "reservoir" for local people to find employment nearby. It is understood that more than 400 people have become workers in the project's production workshop, realizing their desire to find employment at home. (Reporter Xi Chen, Correspondent Xie Tao)

Source: Mass News

The above is the detailed content of Build intelligent transmission industrial robots. For more information, please follow other related articles on the PHP Chinese website!