Core data of this article:Technological breakthrough process; Analysis of technological advantages and disadvantages; Technology development trend forecast, etc.

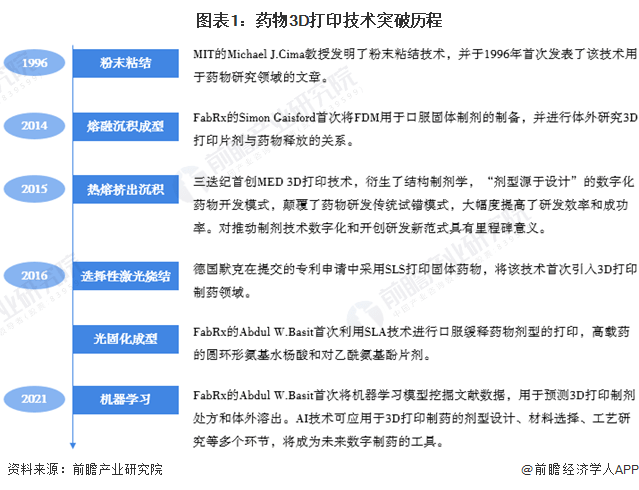

1. The development history of pharmaceutical 3D printing technology

3D printing technology is also called additive manufacturing technology. It is based on digital models constructed by computers and produces three-dimensional entities through "layered printing and layer-by-layer superposition". Pharmaceutical 3D printing technology is a technology that applies 3D printing technology to the pharmaceutical process. It is a bottom-level pharmaceutical technology innovation. The emergence of this technology has led to changes in the entire pharmaceutical process.

The earliest drug 3D printing technology was the powder bonding technology invented by Professor Michael J. Cima of MIT. He first published an article on the use of this technology in the field of drug research in 1996. Since its development, the breakthrough process of pharmaceutical 3D printing technology is as follows:

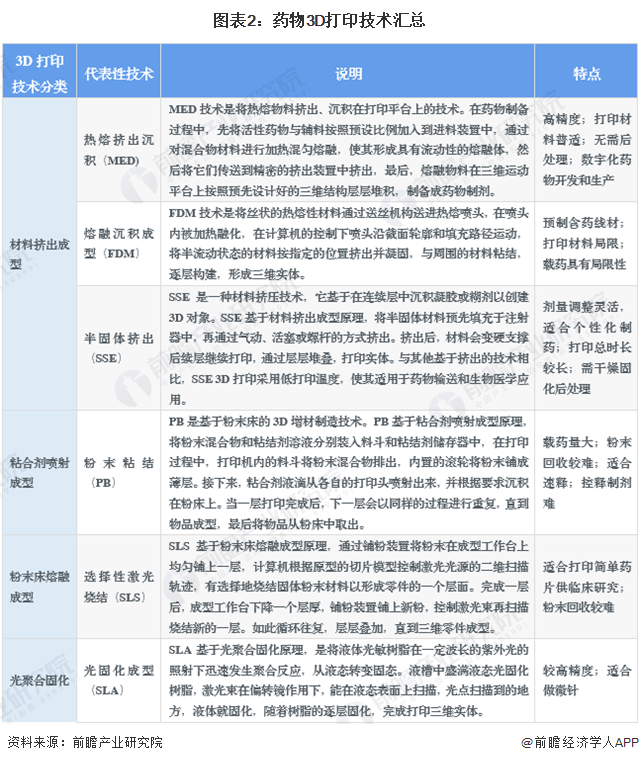

2. Overview of drug 3D printing technology

According to the classification standards of the American Society for Testing and Materials (ASTM) F42 Additive Manufacturing Technical Committee, currently, 3D printing technology can be divided into 7 categories: material extrusion molding technology, binder injection molding technology, and powder bed fusion molding. technology, photopolymerization curing technology, material injection molding technology, direct energy deposition technology and thin film lamination technology. Among them, four types of 3D printing technologies: material extrusion molding technology, binder injection molding technology, powder bed fusion molding technology and photopolymerization curing technology are used in the pharmaceutical field. Their representative technical branches and technical characteristics are as follows:

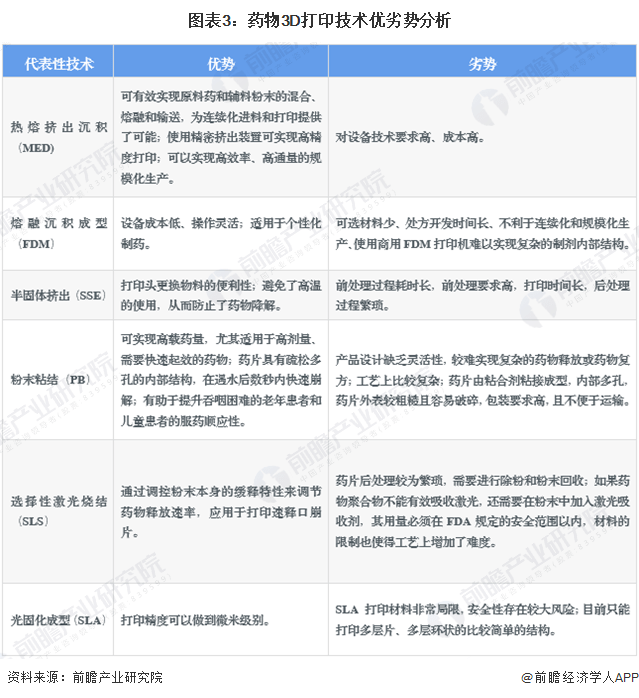

3. Analysis of the advantages and disadvantages of drug 3D printing technology

Compared with traditional preparation technology, drug 3D printing technology has attracted many pharmaceutical companies and research institutions to explore it due to its advantages in product design complexity, personalized drug delivery and on-demand manufacturing. Among them, Fused Deposition Modeling (FDM) is one of the most popular 3D printing technologies and is widely used in drug 3D printing research. However, due to its limited number of optional materials, it is not conducive to continuous and large-scale production, and the accuracy of drug printing is poor. Limitation, FDM technology has been truly applied to the development and commercial production of pharmaceutical products. Therefore, new 3D printing technologies such as hot melt extrusion deposition (MED), direct powder extrusion (DPE) and melt drip molding (MDD) have emerged. born. The advantages and disadvantages of each technology are compared as follows:

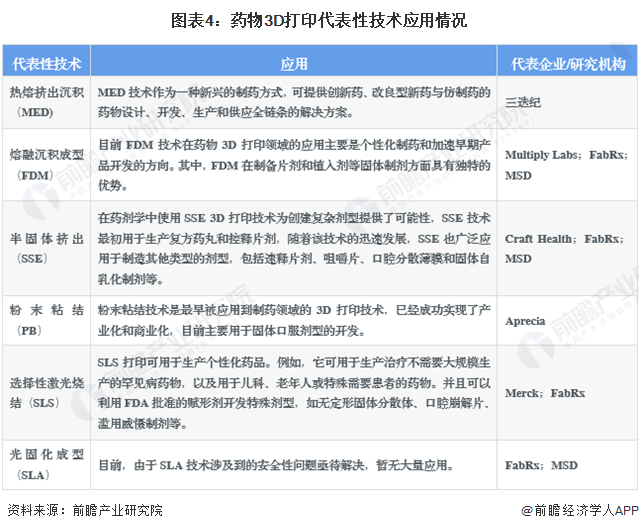

4. Application of drug 3D printing technology

Currently, the application status of representative pharmaceutical 3D printing technologies and the corresponding representative companies and research institutions are as follows:

The current status and development trends of pharmaceutical 3D printing technology are summarized as follows:

Currently, in the field of pharmaceutical 3D printing, material-based extrusion molding technologies such as hot melt extrusion deposition (MED), fused deposition modeling (FDM) and semi-solid extrusion (SSE) have become mainstream trends. Among them, MED is the most widely applicable technology with the greatest clinical application value among pharmaceutical 3D printing technologies. In the future, with the development of the information technology industry, artificial intelligence technology will gradually be applied to various aspects such as dosage form design, material selection and process research of 3D printing pharmaceuticals, thereby realizing the possibility of digital smart pharmaceuticals

Please refer to Qianzhan Industry Research Institute's "" for more research and analysis on this industry

Qianzhan Industry Research Institute also provides consulting and other solutions. When quoting the content of this article, formal authorization from the Qianzhan Industry Research Institute is required, including any public information disclosures such as prospectuses and company annual reports

In [Forward-looking Economist APP], you can find more in-depth industry analysis and interact with 500 economists and senior industry researchers

The above is the detailed content of Analysis of the current status and development trends of the global pharmaceutical 3D printing technology market in 2023 AI technology will promote the possibility of digital smart pharmaceuticals. For more information, please follow other related articles on the PHP Chinese website!